In today’s rapidly advancing technological landscape, one cannot overlook the remarkable capabilities of servo motors with encoders. These cutting-edge devices have revolutionized various industries by providing precise control and feedback mechanisms for motion control systems.

Click to find more about servo motor with encoder.

The Marvels of Servo Motor with Encoder

Servo motors with encoders are highly sophisticated electromechanical devices that combine the power of a motor and an encoder in a single unit. The encoder is responsible for providing accurate position, speed, and direction feedback to the motor controller, enabling precise control over its movement.

This technology has found extensive applications in robotics, CNC machines, 3D printers, and other automated systems where precision and accuracy are paramount. By utilizing closed-loop control algorithms based on encoder feedback, servo motors can achieve exceptional positional accuracy and dynamic performance.

Leadshine: Pioneering Innovation in Motion Control

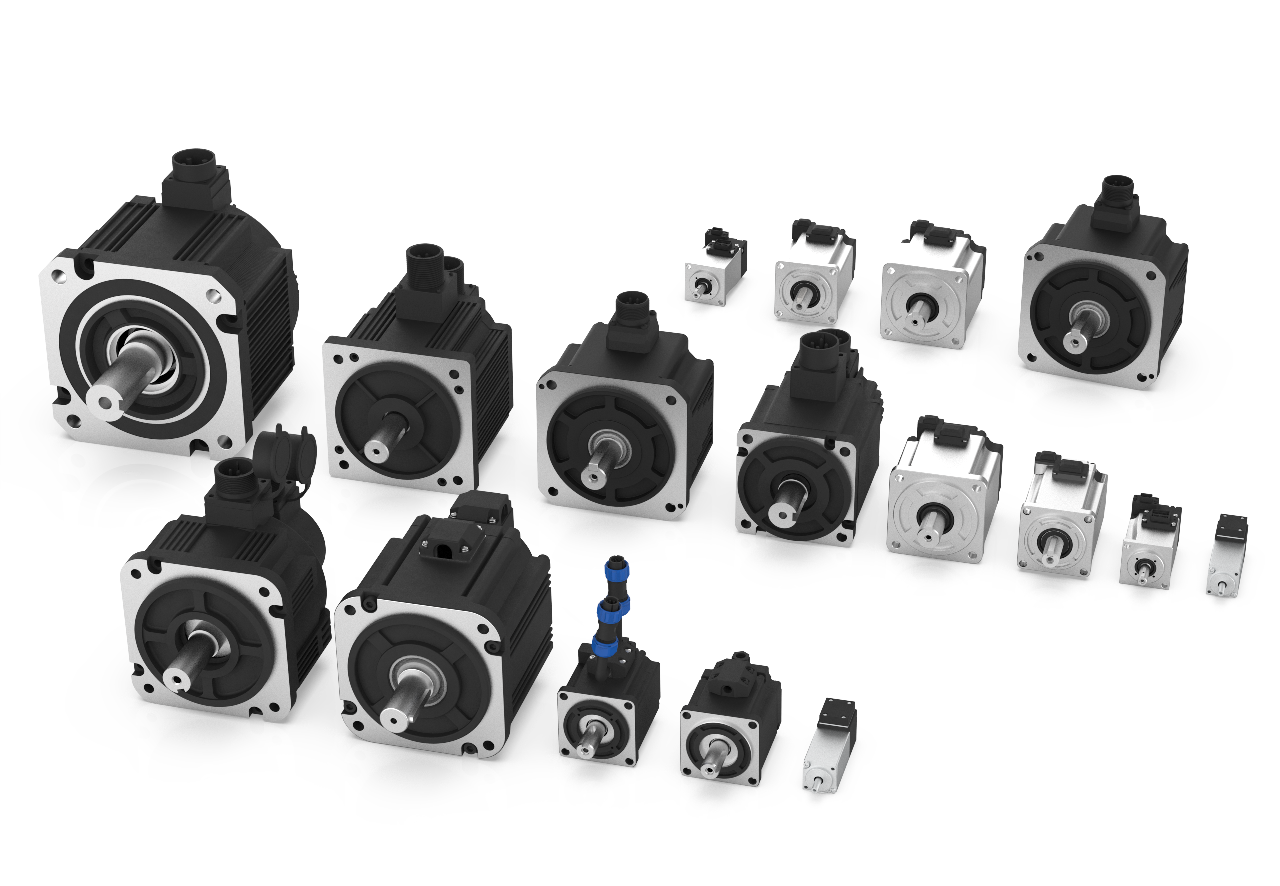

When it comes to servo motors with encoders, Leadshine stands out as a leading manufacturer renowned for their high-quality products. With years of expertise in motion control solutions, Leadshine has consistently pushed boundaries to deliver state-of-the-art technologies that meet industry demands.

Their range of servo motors with encoders offers unparalleled performance characteristics such as high torque density, low inertia design, and advanced communication interfaces. These features make them ideal choices for demanding applications requiring rapid acceleration/deceleration cycles or precise positioning tasks.

Elevating Industrial Automation Systems

industrial automation systems heavily rely on servo motors with encoders to enhance productivity and efficiency. By integrating these powerful devices into assembly lines or robotic arms, manufacturers can achieve seamless coordination between different components while ensuring optimal precision throughout the process.

Servo motors equipped with encoders enable real-time monitoring and adjustment of position, speed, and torque. This capability allows industrial automation systems to adapt swiftly to changing conditions, reducing downtime and enhancing overall operational performance.

The Future is Here

In conclusion, servo motors with encoders have revolutionized the way industries operate by providing unprecedented control over motion systems. With Leadshine’s cutting-edge solutions leading the way in innovation, these devices continue to shape the future of industrial automation. As technology advances further, we can expect even more remarkable developments that will further enhance precision and efficiency in various sectors.