What is Prototype CNC Machining?

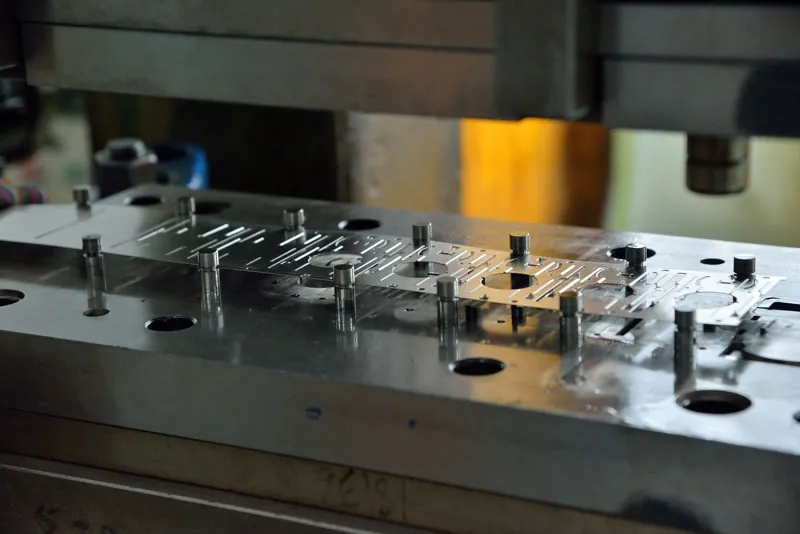

Prototype CNC machining is a game-changer in the world of manufacturing. It’s a process that uses computer-controlled machines to create precise parts and prototypes from a variety of materials. Imagine being able to design a complex part and then see it come to life within days! This technology not only streamlines the production process but also allows for high accuracy and repeatability, making it a favorite among engineers and designers. Whether you’re a startup looking to test a new product or an established company seeking to improve existing designs, prototype cnc machining provides opportunities to innovate your way to success.

Why Choose Prototype CNC Machining?

The benefits of opting for prototype CNC machining are plentiful. For starters, the speed at which prototypes can be produced gives businesses a competitive edge. Instead of waiting weeks or months to see a design come to fruition, CNC machining can reduce that time significantly. Additionally, the precision achieved ensures that every prototype is reliable and functional, addressing potential issues before mass production begins. For example, imagine testing a new automotive part that needs to fit perfectly with others; CNC machining guarantees the accuracy needed. This can save costs and time down the line, proving that investing in prototype cnc machining is indeed worthwhile.

Diving into CNC Machine Services

When it comes to bringing ideas to life, cnc machine services are an essential component. They cater to a wide range of industries, from aerospace to consumer electronics. Think about how these services operate—professionals use a variety of machines to cut, mill, and shape designs to meet specific requirements. This adaptability is particularly advantageous for small businesses or startups that may not have the resources for large-scale production. Using CNC machining can minimize waste and increase efficiency, taking the worry out of production. Plus, with the support of skilled technicians, businesses can optimize their designs to maximize functionality.

CNC Machine Services – What You Need to Know

If you’re considering cnc machine services for your project, it’s essential to choose a provider that understands your unique needs. Look for companies that offer custom solutions, as every project has its own specific requirements. An excellent CNC service provider will work closely with you, offering insights on materials, design adjustments, and production timelines. For instance, the ability to quickly iterate on designs saves you from costly mistakes and allows rapid prototyping that meets market needs. This level of service ensures that you’re not just another number—they prioritize your success and satisfaction, leading to strong business relationships and superior results across the board.

Conclusion – Why APT-Mold Stands Out

In conclusion, if you’re in the market for top-notch prototype CNC machining and CNC machine services, look no further than APT-Mold. Their expertise and commitment to quality set them apart in the industry. With advanced technology at their disposal and an emphasis on customer satisfaction, APT-Mold provides the supply advantages that can elevate your projects to new heights. Don’t settle for ordinary; choose a manufacturer that understands your needs and delivers exceptional results. With APT-Mold, you’re not just getting a service; you’re gaining a partner invested in your success.